NOV推出用于二疊系應(yīng)用的MWD系統(tǒng)

二疊紀(jì)盆地對具有電磁(EM)和泥漿脈沖(MP)數(shù)據(jù)傳輸能力的MWD系統(tǒng)的需求正在增加。ReedHycalog是NOV的Wellbore Technologies部門的一個業(yè)務(wù)部門,開發(fā)了用于此類應(yīng)用的BlackStar II雙遙測MWD工具。

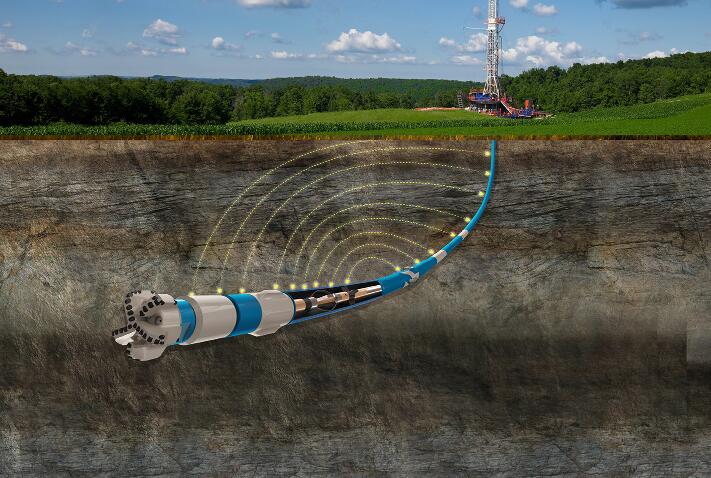

BlackStar II雙遙測MWD工具結(jié)合了EM和MP數(shù)據(jù)傳輸能力,在具有挑戰(zhàn)性的二疊紀(jì)鉆井條件下進(jìn)行連續(xù)鉆井作業(yè)。雙遙測工具的模塊化設(shè)計(jì)允許靈活配置工具串時(shí)將操作能力大化,允許在井下測量定向、鉆井和地層數(shù)據(jù),并以電磁波或壓力脈沖傳輸?shù)降孛妗.?dāng)使用低頻EM波時(shí),該工具通過地殼將信息發(fā)送到地面。這些信息在地面天線處被接收、解碼,由計(jì)算機(jī)處理并傳送給司鉆的讀出顯示器,不會阻塞泥漿或電線傳輸。EM工具沒有移動部件,允許用于空氣鉆井條件下或泥漿脈沖(MP)工具無法工作的高損耗循環(huán)材料環(huán)境。另外,可以在連接過程中傳輸調(diào)查結(jié)果,大限度地減少與傳統(tǒng)MP工具相關(guān)的非生產(chǎn)時(shí)間。

雙遙測工具使得定向鉆機(jī)能夠?qū)崿F(xiàn)更高的遙測速度,并且通過EM遙測技術(shù)可以縮短測量時(shí)間,而不用擔(dān)心會出現(xiàn)信號中斷。與其他雙遙測工具不同的是,新工具是完全可回收的,這樣可以減少昂貴的漏洞事件風(fēng)險(xiǎn)。在設(shè)計(jì)該工具時(shí),NOV的主要目標(biāo)之一是使客戶能夠利用其現(xiàn)有的非磁性箍圈,泥漿脈沖器和通用的井底定向潛水器,從而降低實(shí)現(xiàn)雙遙測能力所需的投資。在二疊系中,靈活性是關(guān)鍵,而該工具的增強(qiáng)功能和成本效益的提高,以及多樣化的電源管理使得定向鉆機(jī)有明顯的優(yōu)勢,非常適合。

一家定向供應(yīng)商使用雙遙測工具來解決了信號強(qiáng)度和電池壽命問題。以前嘗試使用其他工具進(jìn)行EM遙測一直不成功,但使用新工具后,可變電壓和電流輸出允許靈活地將信號范圍擴(kuò)展到側(cè)面。電池消耗得到了優(yōu)化,使工具達(dá)到13,000英尺以上的總深度,成功的EM傳輸提供了比傳統(tǒng)的泥漿脈沖更新速率更快的定向和伽馬測量。另外,由于系統(tǒng)的雙遙測多重性,操作員減少了非生產(chǎn)時(shí)間,有效地降低了設(shè)備更換的跳閘次數(shù)。

關(guān)于鼎恒石油

若需要購買井下產(chǎn)品或需要了解產(chǎn)品詳細(xì)參數(shù)及相關(guān)疑問,可直接進(jìn)入鼎恒石油官網(wǎng)咨詢網(wǎng)站客服或者撥打銷售熱線18000522697。

四川鼎恒石油機(jī)械設(shè)備有限公司(http://873817.com)是一家擁有進(jìn)出口經(jīng)營權(quán),長期從事國內(nèi)外石油天然氣設(shè)備和配件的專業(yè)銷售公司。鼎恒石油公司總部設(shè)在四川成都,在加拿大大不列顛哥倫比亞省成立了分公司。我公司與多家世界知名制造廠商建立了緊密的合作關(guān)系。

注:該文章由鼎恒石油編譯,轉(zhuǎn)發(fā)須注明出處。

附英文原文:

NOV develops MWD system for Permian applications

HOUSTON -- Demand in the Permian basin for an MWD system with both electromagnetic (EM) and mud-pulse (MP) data transmission capabilities is increasing. ReedHycalog, a business unit of National Oilwell Varco’s Wellbore Technologies segment, developed the BlackStar II dual-telemetry MWD tool for use in such applications.

The BlackStar II dual-telemetry MWD tool combines the capabilities of both EM and MP data transmission to provide continuous drilling in challenging Permian drilling conditions. The dual-telemetry tool’s modular design allows flexibility in configuring the toolstring to maximize operational capabilities, allowing directional, drilling, and formation data to be measured downhole and transmitted to surface as either EM waves or pressure pulses. When using low-frequency EM waves, the tool sends information to the surface through the earth’s crust. The information is received at a surface antenna, decoded, and processed by a computer and distributed to the driller’s readout display without the encumbrance of mud or wire transmission. EM tools have no moving parts, allowing for use in air-drilling conditions or high lost-circulation material environments where mud-pulse (MP) tools are rendered inoperable. In addition, surveys can be transmitted during connections, minimizing the nonproductive time associated with conventional MP tools.

The dual-telemetry tool enables directional drillers to achieve the higher telemetry speeds and reductions in survey time made possible by EM telemetry, without risking a trip out of hole for signal interruption. Unlike other dual-telemetry tools, the new tool is fully retrievable, which reduces the risk of costly lost-in-hole events. When designing the tool, one of NOV’s primary objectives was to enable customers to utilize their existing inventory of nonmagnetic collars, mud pulsers, and universal bottomhole orientation subs, thereby reducing the investment necessary to offer dual-telemetry capabilities. The tool’s enhanced functionality and improved cost-effectiveness is ideal for use in the Permian, where flexibility is key and diverse power management options present directional drillers with a distinct advantage.

A directional provider used the dual-telemetry tool to address signal strength and battery-life concerns on a long lateral. Previous attempts to utilize EM telemetry with other tools had been unsuccessful, but with the new tool, variable voltage and current output allowed flexibility to extend the signal range into the lateral. Battery consumption was optimized, allowing the tool to reach total depth at more than 13,000 ft, and successful EM transmission provided directional and gamma measurements much faster than conventional mud-pulse update rates. Additionally, the operator eliminated nonproductive time due to the dual-telemetry redundancy of the system, effectively eliminating the need to trip for an equipment change.