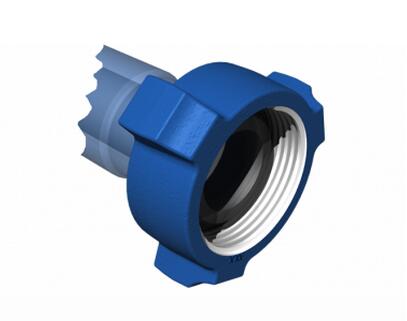

SPM EXL翼形螺母

SPM EXL翼形螺母正在申請專利,其設計旨在降低導致傳統翼形螺母故障的重力,同時提供可實施在新的和使用中的客戶資產上的解決方案。

產品概述

設計挑戰

翼形螺母故障有兩個主要來源:周期性負荷引起的疲勞裂紋和錘擊產生的過大負載沖擊。與泵送操作期間產生的典型脈動相配合的連續側向載荷力對鐵錘設備產生顯著的應力水平。因此,疲勞裂紋形成可能發生在螺紋根部,其可以軸向傳播并導致意外的分離。

解決方案

SPM EXL翼形螺母正在申請專利,有助于從源頭解決故障,并在內螺紋上具有全根半徑,以幫助小化應力濃度。這種設計特征還有另外的益處,即增大間隙以增加螺紋中積聚的碎屑,有助于正確組裝。向前延伸的稠化劑凸耳與較大的外徑配對可通過抑制傳播路徑減少裂紋,并提供更大的表面積來吸收鐵錘沖擊載荷。 SPM EXL翼形螺母可以改進現有的SPM產品,并且與大多數現有的具有相當尺寸和壓力等級的鐵錘聯接頭兼容。

設計確認

SPM EXL翼形螺母的設計旨在使關鍵位置的應力濃度小化。通過綜合分析證實,該設計減少的疲勞應力導致故障前的循環增加了235%。這種疲勞分析主要基于1500 lb. 交替側向載荷。

應用

壓裂

固井

油井服務

關于鼎恒石油

四川鼎恒石油是Weir SPM的授權代理商,若需要購買SPM產品或需要了解產品詳細參數及相關疑問,可直接進入鼎恒石油官網咨詢網站客服或者撥打銷售熱線18000522697。

四川鼎恒石油機械設備有限公司(http://873817.com)是一家擁有進出口經營權,長期從事國內外石油天然氣設備和配件的專業銷售公司。鼎恒石油公司總部設在四川成都,在加拿大大不列顛哥倫比亞省成立了分公司。我公司與多家世界知名制造廠商建立了緊密的合作關系。

注:該文章由鼎恒石油編譯,轉發須注明出處。

附英文原文:

SPM® EXL Wing Nut

The patent pending SPM® EXL wing nut is designed to reduce stresses that have been a cause of legacy wing nut failures, while providing a solution that can be implemented on new and in-use customer assets.

Overview

Design Challenges

There are two primary sources of wing nut failure: fatigue cracks from cyclical loading and excessive load impact from hammer strikes. Continual side load forces paired with the typical pulsations produced during pumping operations create significant levels of stress on hammer unions. Consequently, fatigue crack formations may develop at the thread root which can propagate axially and lead to an unexpected separation.

The Solution

The patent pending SPM® EXL wing nut helps address failures at their source and features a full root radius on the internal threads to help minimize stress concentrations. This design feature also provides the additional benefit of added clearance for debris accumulation in the threads, assisting with proper assembly. Thicker lugs that extend forward, paired with a larger outside diameter, reduce cracking by suppressing the propagation path and provide a greater surface area to absorb hammer impact loads. The SPM® EXL wing nut can be retrofitted to existing SPM® product and is compatible with most existing hammer union connections of comparable size and pressure rating.

Design Validation

The SPM® EXL wing nut is engineered to minimize stress concentrations at critical locations. A comprehensive analysis confirmed the design reduced fatigue stress resulting in a 235% increase in cycles prior to failure. This fatigue analysis is based on 1,500 lb. alternating side load.

Applications

Fracking

Cementing

Well Service